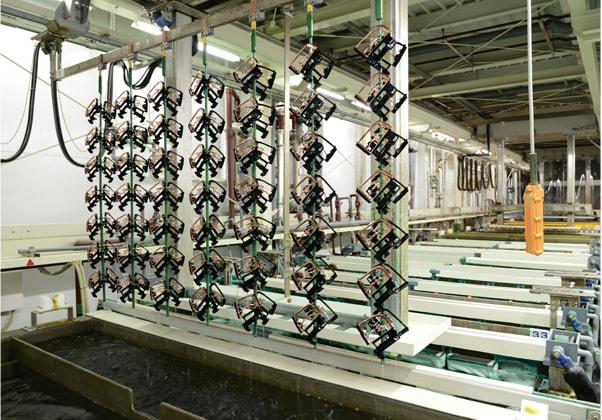

Fully automatic Plastic Plating line

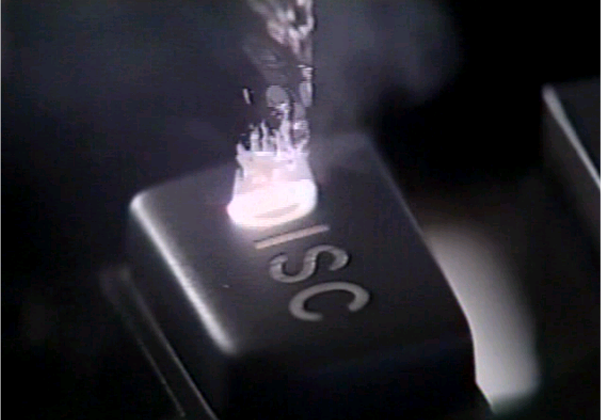

Laser Etching

3D vision measuring instrument

Assembly line at oversea factories

- Products Information

-

Plastic Plating

- Plastic Plating

Production of Plastic molding

Plastic Plating

Painting, laser Etching and assembly

Complete Chrome-Ⅵ free

Silica-based Coating

-

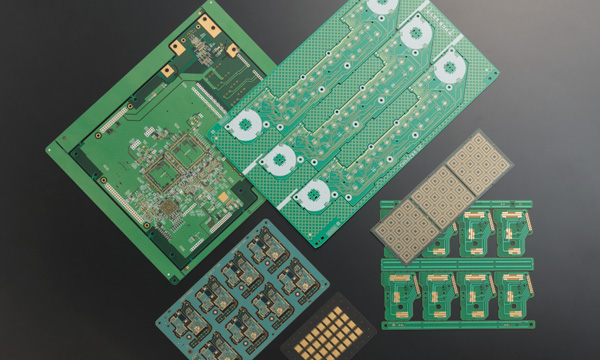

Electronic Circuit Board

- Electronic Circuit Board

Electroless Ni-Au plating, terminal plating and bond Au plating

Flexible board: drilling, through-hole copper plating, gold plating

Electronic Circuit Board: through-hole copper plating

-

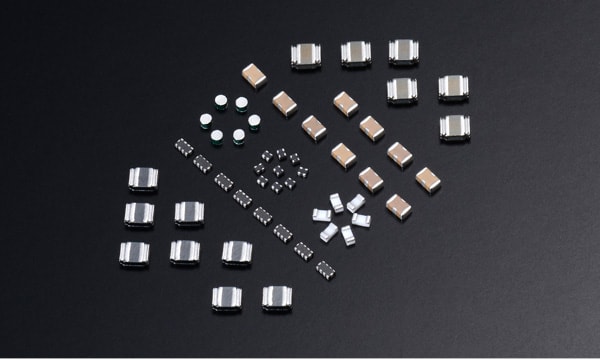

Electronic Components / Semiconductors

- Electronic Components / Semiconductors

Bump plating

Ceramic board plating

Plating for SMD terminals

Ni-hoop plating (secondary battery Electrode)

-

Metal Parts

- Metal Parts

Zinc and zinc-nickel plating

Nickel and tin plating

Alumite and alodine

Gold and silver plating

-

You can find Taiyo products everywhere

You can find Taiyo products everywhere

In Cars

In Cars smart phones

smart phones houses

houses

- Close

-

Plastic Plating

- Company Information

- Business Location

- Research & Development

- Quality Control

- Environment / ISO

- CSR